Unlocking Industrial Efficiency with Laser Cleaning Machines: Precision and Power by LaserChina

November 28, 2025 | by IoT Development Company

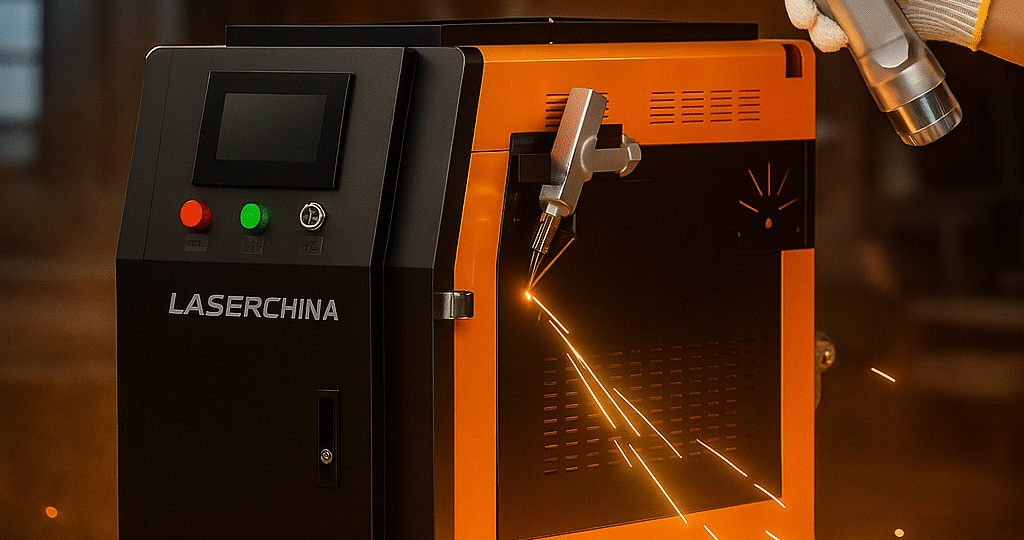

In modern industrial environments, surface cleaning and material preparation play a critical role in ensuring product quality and operational efficiency. Traditional cleaning methods like chemical solutions, abrasive blasting, or mechanical scrubbing often fall short due to inefficiency, environmental concerns, or potential damage to delicate surfaces. Enter the laser cleaning machine, a revolutionary solution that combines precision, speed, and eco-friendliness.

LaserChina, a leading manufacturer and supplier of high-quality laser parts and systems, specializes in providing complete laser solutions tailored for industrial, manufacturing, and repair applications. From laser lenses and mirrors to CO2 and fiber laser tubes, LaserChina equips users with components that maximize performance and reliability.

What is a Laser Cleaning Machine?

A laser cleaning machine is a device that uses high-energy laser beams to remove contaminants, rust, paint, or oxide layers from a material surface without physical contact. Unlike conventional methods, laser cleaning offers precise control, minimal waste, and non-abrasive treatment, making it ideal for sensitive materials such as metals, composites, and ceramics.

Key Advantages:

-

Non-contact and precise cleaning: Prevents surface damage and maintains material integrity.

-

Environmentally friendly: Eliminates the need for chemicals and reduces hazardous waste.

-

Cost-effective operation: Reduces labor and consumables while increasing throughput.

-

Versatile applications: Suitable for rust removal, paint stripping, mold cleaning, and more.

LaserChina’s Expertise in Laser Cleaning Solutions

LaserChina stands out as a trusted provider of laser cleaning machines and components due to its commitment to innovation, quality, and customer support. Their range of products ensures that industrial users can optimize their cleaning processes with the highest efficiency:

-

High-precision laser lenses and mirrors: Enhance beam quality and cleaning performance.

-

CO2 and fiber laser tubes: Deliver powerful, stable laser output for demanding cleaning tasks.

-

Laser cutting and cleaning heads: Ensure accurate and uniform energy distribution across surfaces.

-

Customizable solutions: LaserChina can design laser cleaning setups tailored to specific industrial needs.

With decades of experience in laser technology, LaserChina guarantees durability, precision, and ease of integration, making it a preferred choice for manufacturers, repair technicians, and industrial operators worldwide.

Applications of Laser Cleaning Machines

Laser cleaning technology is versatile and widely used across multiple industries:

-

Automotive industry: Removing rust, paint, or residues from vehicle parts.

-

Electronics and semiconductors: Cleaning delicate components without chemical damage.

-

Metal fabrication: Preparing surfaces before welding, coating, or finishing.

-

Cultural heritage restoration: Safely cleaning artifacts and historical items.

This wide range of applications demonstrates the adaptability of laser cleaning machines in enhancing productivity and preserving material quality.

FAQs

Q1: Can laser cleaning machines damage the surface?

A1: When used correctly, laser cleaning is non-abrasive and precise, preventing surface damage. Proper settings and components from trusted suppliers like LaserChina ensure safe operation.

Q2: What materials can be cleaned with a laser cleaning machine?

A2: Metals, alloys, composites, ceramics, and even some delicate surfaces can be effectively cleaned using the right laser parameters.

Q3: How does a laser cleaning machine compare to traditional cleaning methods?

A3: Laser cleaning is faster, environmentally friendly, and more precise, reducing labor and consumable costs while improving surface quality.

Q4: Do I need specialized training to operate a laser cleaning machine?

A4: Basic training on laser safety and operation is recommended. LaserChina provides guidance and technical support for safe and effective use.

Q5: Can LaserChina provide replacement parts for my laser cleaning system?

A5: Yes, LaserChina offers high-quality laser lenses, mirrors, tubes, and other components to maintain and upgrade existing laser cleaning machines.

Explore LaserChina’s Laser Cleaning Solutions

For industrial operators, repair technicians, and manufacturers seeking precision and efficiency, a laser cleaning machine from LaserChina is the ultimate choice. With expert guidance, premium components, and reliable support, LaserChina helps you optimize your laser systems for maximum performance.

Contact LaserChina today to explore professional laser parts, accessories, and complete solutions tailored to your industrial cleaning and processing needs.

RELATED POSTS

View all