High-Precision Manufacturing Redefined with Advanced Metal Laser Cutting Machine Technology

October 31, 2025 | by IoT Development Company

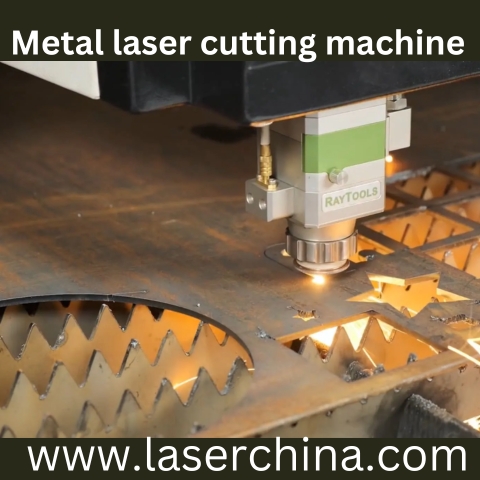

In the evolving world of modern manufacturing, the metal laser cutting machine has become a cornerstone of precision, efficiency, and flexibility. Whether for industrial fabrication, custom metalwork, or high-volume production, this technology delivers cutting performance that traditional methods cannot match. The combination of speed, accuracy, and minimal material waste has made laser cutting one of the most demanded processes in industries across the globe.

A metal laser cutting machine operates by focusing a high-powered laser beam on a metal surface, melting, burning, or vaporizing the material along a programmed path. This process produces fine, clean cuts with incredible accuracy. Unlike mechanical cutting, there is no physical contact between the tool and the workpiece, reducing wear and tear on tools and maintaining consistency throughout long production runs.

The Technology Behind Metal Laser Cutting

At the heart of every metal laser cutting machine is a high-intensity laser source. The most common types include CO₂, fiber, and Nd:YAG lasers, each suited for different cutting tasks and materials. Fiber lasers, in particular, have gained prominence due to their efficiency, energy-saving capability, and ability to cut reflective metals such as aluminum, brass, and copper with minimal distortion.

These machines integrate advanced motion control systems, precision optics, and computer numerical control (CNC) programming. The CNC interface allows operators to import design files directly from CAD software, converting complex geometries into executable cutting paths. This level of automation ensures repeatable, error-free results, even for intricate shapes or delicate metal components.

Modern systems are also equipped with smart sensors and monitoring technology. These tools continuously analyze cutting parameters, adjusting power, focus, and gas pressure in real time. The result is consistently high-quality output, even under demanding production environments.

Industrial Applications

The metal laser cutting machine serves as a backbone in multiple industrial sectors. From automotive manufacturing to construction, its applications are nearly limitless. In the automotive sector, laser cutting ensures high-precision body parts, brackets, and interior components that meet strict tolerances. Aerospace manufacturers rely on it for creating lightweight yet strong metal structures, essential for both safety and fuel efficiency.

In architectural metalwork, laser cutting machines enable creative freedom for producing decorative panels, gates, and façade designs with unmatched detail. The electronics industry utilizes this technology for producing fine components like connectors and enclosures. In shipbuilding and heavy machinery production, it plays a vital role in cutting thick metal plates efficiently and accurately.

For smaller businesses, the machine enables on-demand manufacturing of custom parts and prototypes without the need for expensive molds or tooling. This flexibility supports the growth of creative and small-scale engineering enterprises that can now compete with larger manufacturers.

Precision and Quality in Every Cut

What distinguishes a metal laser cutting machine from conventional methods is its ability to maintain dimensional accuracy and edge quality. The heat-affected zone (HAZ) is minimal, which prevents warping or distortion of the metal. This is particularly important when cutting thin sheets or working with materials sensitive to heat.

Moreover, laser cutting ensures burr-free edges, eliminating or reducing the need for secondary finishing processes. This clean finish translates into lower production time and cost while improving the visual and functional quality of the final product.

With precise control over beam intensity and cutting speed, these machines can handle a wide range of metals — from stainless steel, mild steel, and aluminum to titanium and copper alloys. Each material can be processed according to specific requirements, ensuring optimal results for various industrial standards.

Integration with Automation and Smart Manufacturing

Today’s metal laser cutting machine is more than just a tool — it’s part of an integrated production system. With Industry 4.0 principles, these machines can communicate with other manufacturing equipment, providing real-time data and analytics. Operators can monitor machine performance remotely, manage maintenance schedules, and even predict potential issues before they occur.

Automated loading and unloading systems further enhance productivity by minimizing manual handling. Some advanced setups also feature robotic arms that pick and place parts directly into downstream processes such as bending, welding, or assembly. This integration results in smoother production flow, fewer errors, and higher throughput.

Cloud-based control systems and digital monitoring allow companies to track material usage, cutting times, and power consumption. Such insights support cost management and sustainability goals, helping businesses optimize their operations.

Sustainability and Material Efficiency

Sustainability has become a key focus in modern manufacturing. The metal laser cutting machine supports environmentally responsible production by reducing material waste and energy consumption. Its precision cutting minimizes scrap, allowing manufacturers to maximize the yield from each metal sheet.

Since laser cutting is a contactless process, it does not produce chips, lubricants, or tool residues, reducing the need for chemical cleaning or disposal. Additionally, the energy efficiency of modern fiber lasers further contributes to a cleaner, more sustainable manufacturing environment.

For companies focusing on eco-friendly production, laser cutting also aligns with recycling strategies. Clean, precise cuts make it easier to reuse metal offcuts and manage waste responsibly.

Training and Operation

Operating a metal laser cutting machine requires a balance of technical skill and understanding of material behavior. While the software simplifies programming and execution, operators must be trained in setup procedures, maintenance routines, and safety protocols.

Most manufacturers offer specialized training programs that cover everything from calibration and gas flow adjustment to interpreting design drawings and optimizing cutting speeds. Safety measures such as protective eyewear, proper ventilation, and secure material handling are integral to ensuring safe operation.

As technology evolves, newer systems come equipped with intuitive interfaces that reduce the learning curve. Operators can now manage complex cutting tasks through touchscreen controls and visual simulation previews before execution, minimizing the risk of errors.

Business Impact and Economic Efficiency

For manufacturers, investing in a metal laser cutting machine is a strategic decision. The combination of automation, precision, and low maintenance cost creates a pathway toward increased profitability. Faster production cycles mean more orders fulfilled in less time, while the ability to handle custom designs opens up new business opportunities.

This machine not only enhances manufacturing capacity but also strengthens competitiveness in industries driven by quality and customization. Whether producing large batches or single prototypes, businesses gain control over their production timeline and consistency.

Many fabrication companies now use laser cutting as a core service offering, expanding into markets like signage, art installations, and industrial prototyping. The versatility and repeatability of the technology make it a valuable asset for long-term growth.

Future of Laser Cutting

As innovation continues, the metal laser cutting machine is expected to evolve with smarter software integration, adaptive automation, and enhanced energy control. Developments in laser power and beam quality are opening new possibilities for thicker materials and hybrid processes combining cutting with marking or engraving.

Artificial intelligence-driven optimization and predictive maintenance will soon become standard features, improving uptime and operational reliability. In parallel, the demand for customized and rapid production across industries ensures that laser cutting remains at the forefront of manufacturing innovation.

Final Thoughts

The metal laser cutting machine stands as a key driver of progress in modern fabrication. Its combination of precision, speed, and adaptability allows industries to meet growing demands for high-quality metal products efficiently. As manufacturing continues to shift toward digital integration and sustainability, this technology provides the foundation for smarter, cleaner, and more flexible production systems.

Whether for large-scale industrial plants or small fabrication workshops, investing in laser cutting technology is a step toward future-ready manufacturing. Its role in shaping metal with accuracy and reliability continues to redefine how the world builds, creates, and innovates.

RELATED POSTS

View all