Top Innovations in Dew Point Measurement Device Technology for 2025

December 6, 2025 | by IoT Development Company

Dew Point Measurement Device is a deceptively central part of many industries, from compressed air quality and industrial gases to semiconductor fabs, pharmaceuticals, meteorology, and environmental monitoring.

As the need for tighter process control and traceability grows, 2025 is shaping up to be a year in which innovations across optics, materials, miniaturization, and connectivity push dew point devices from niche laboratory tools into ubiquitous, smart industrial instruments. Below I highlight the leading innovations shaping the field in 2025 and why they matter.

1. Laser-based TDLAS moves from lab prototypes to robust field instruments

Tunable Diode Laser Absorption Spectroscopy (TDLAS) has been researched for dew/frost-point measurements for years because it measures water vapor directly and can reach very low dew points with fast response times.

Recent papers and commercial developments show TDLAS systems becoming more rugged, compact, and suitable for on-line industrial use, addressing previous barriers such as cost, optical path management, and sensitivity in flowing gas streams. TDLAS instruments now compete with chilled mirror standards for accuracy while offering rapid response and minimal drift, which is attractive for continuous process monitoring.

2. Integrated photonics and miniature chilled-mirror analogues

Miniaturization is not only about shrinking enclosures. Dew Point Measurement Device, researchers have engineered integrated photonics platforms that replicate the chilled-mirror principle on a chip-scale resonator, combining the mirror and thermometer in a single photonic element.

These approaches promise laboratory-grade accuracy in portable packages and open the door to mass-producible, low-power dew point sensors for field and OEM use — useful where traceable accuracy is required but space or power is limited. Early demonstrations indicate ultrahigh accuracy and potential for lower-cost deployment.

3. New thin-film and metal-oxide sensor chemistries for faster, more stable electronic probes

Capacitive thin-film sensors (the classic HUMICAP style) have steadily improved, but 2024–25 saw commercial introductions of advanced thin-film/metal-oxide sensor elements specifically tuned for dew-point and low-moisture environments.

Hyper-Thin-Film (HTF™) aluminum oxide and related metal-oxide coatings provide higher sensitivity, better temperature compensation, and longer-term stability in harsh gas streams, reducing calibration frequency and improving uptime for industrial transmitters. These sensors bridge the gap between low-cost capacitive probes and high-accuracy chilled mirror meters.

4. Smarter chilled-mirror instruments: automation, contamination mitigation, and lower maintenance

Chilled-mirror hygrometers remain the gold standard for dew-point accuracy and traceability. The innovation trend for 2025 isn’t replacing them so much as making them easier to use continuously: automated mirror-cleaning cycles, improved Peltier control, optical detection algorithms that better discriminate frost vs.

dew, and modular heads that tolerate contaminants. Manufacturers have also improved flow-through conditioning and software-driven calibration assistants so chilled-mirror systems can be deployed in more industrial contexts with reduced operator intervention.

5. Edge intelligence, IoT integration and predictive maintenance

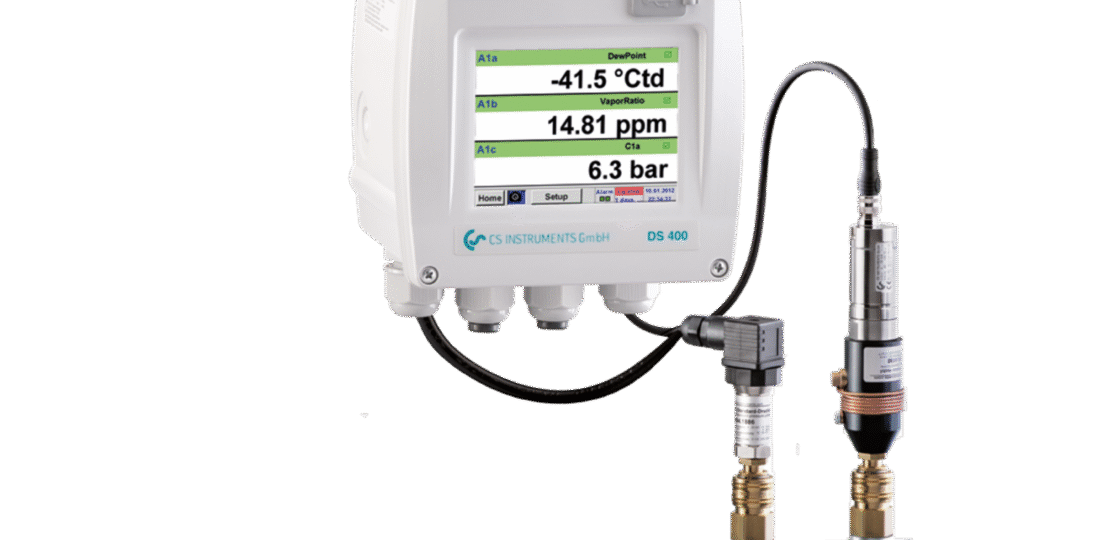

Dew Point Measurement Device are increasingly part of broader digital ecosystems. New transmitters ship with native Ethernet/OPC UA or wireless stacks, built-in edge analytics, and support for predictive maintenance. This means dew point instruments can now flag sensor drift, predict contamination events, and trigger process adjustments automatically — lowering unplanned downtime and saving calibration costs.

Vendors are also packaging standardized data formats to make hygrometer data immediately useful in plant SCADA and cloud analytics. The move toward connected, smart transmitters is accelerating market adoption.

6. Wider dynamic range and extreme low-dew performance

Industrial users increasingly need accurate readings at very low absolute moisture levels (e.g., gas drying for inert-gas supply or semiconductor processes). Innovations in optical methods (TDLAS), improved chilled-mirror sensitivity, and specialized low-outgassing sampling paths have extended reliable measurement ranges down to extremely low dew and frost points while maintaining traceability. This allows suppliers to consolidate instruments instead of deploying separate low-range analyzers.

7. Easier calibration, traceability and on-site validation

Dew Point Measurement Device, meeting regulatory and quality standards means instruments must be traceable. Device makers now offer on-board self-test routines, automated comparison modes (e.g., built-in references or swap-in validation heads), and streamlined ISO/ISO-17025 calibration workflows. This reduces the friction for labs and plants that must demonstrate measurement traceability without frequent off-site calibration. Chilled-mirror makers still lead on primary-standard traceability, but other technologies are closing the gap.

8. Market momentum and adoption trends

Market analyses show the dew point and smart-sensor market growing strongly in 2024–25 as industries demand higher precision and automation, particularly in semiconductor, pharma, and industrial-gas segments. This growth is fueling R&D investment and faster product cycles, so new instrument classes are rapidly transitioning from prototype to product lines.

What this means for users in 2025

For process and reliability engineers, the implications are straightforward: you can now pick from a broader palette of devices tailored to accuracy, speed, and connectivity needs. If traceability and the absolute lowest uncertainty matter, modern chilled-mirror systems (with improved automation) remain best-in-class.

If you need fast, non-contact, continuous monitoring with minimal drift in flowing gas streams, TDLAS instruments are a compelling alternative. For OEMs and field applications where price, size, and power matter, integrated photonics and improved thin-film sensors make lab-grade measurements feasible in portable packages.

Final note

Dew Point Measurement Device, the overall trend in 2025 is convergence: optical, electronic, and materials innovations each solve different historical weaknesses, and connectivity layers tie measurement into smarter control systems. That convergence is turning dew-point measurement from a specialized metrology task into an integrated part of modern industrial sensing strategies, more accurate, easier to manage, and far more actionable than ever before.

RELATED POSTS

View all